Cable Process Flow Chart . First of all, let’s clarify two. the cable is dried, and the top layer of the jacket is heated slightly so that printer markings can be imprinted on it. in this post, we’re going to talk about the common and crucial steps of cable manufacturing. Figure 2 shows the production. this research paper aims to explore the different types of cables, their applications, and technical and physical data. this process is crucial in ensuring that cables meet the required standards for performance, safety, and durability. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. the manufacture of electrical cables, wire and wire products is a highly specialized process that requires the use of.

from www.researchgate.net

design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. the cable is dried, and the top layer of the jacket is heated slightly so that printer markings can be imprinted on it. this research paper aims to explore the different types of cables, their applications, and technical and physical data. Figure 2 shows the production. First of all, let’s clarify two. in this post, we’re going to talk about the common and crucial steps of cable manufacturing. the manufacture of electrical cables, wire and wire products is a highly specialized process that requires the use of. this process is crucial in ensuring that cables meet the required standards for performance, safety, and durability.

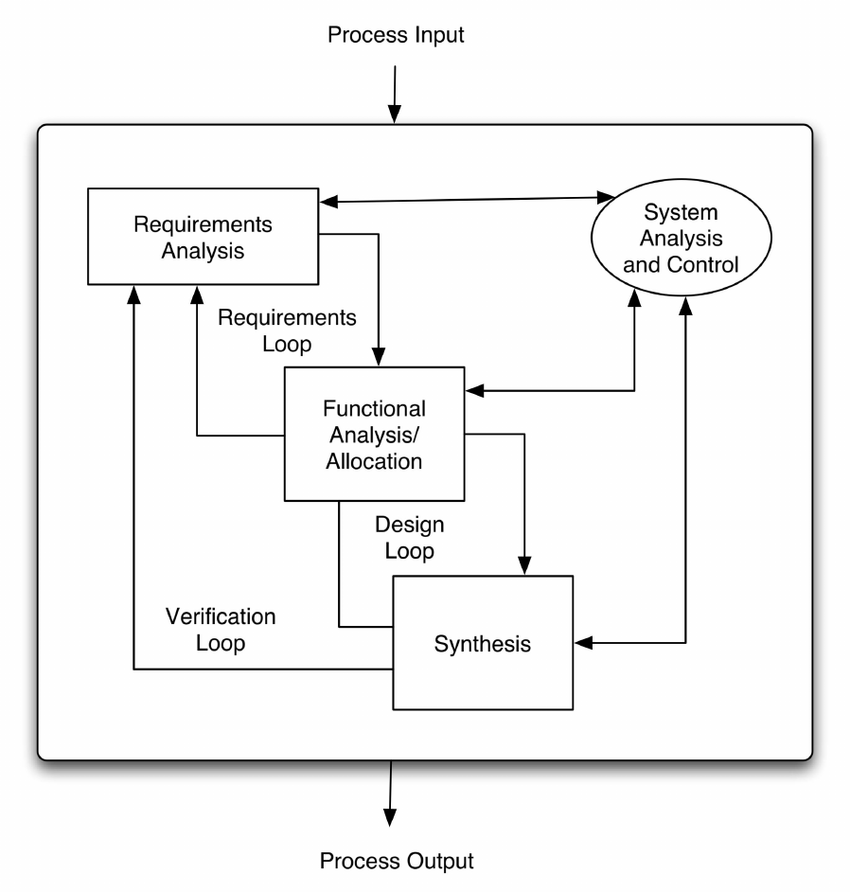

Flow chart showing the major stages of the system engineering process

Cable Process Flow Chart design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. in this post, we’re going to talk about the common and crucial steps of cable manufacturing. Figure 2 shows the production. First of all, let’s clarify two. this process is crucial in ensuring that cables meet the required standards for performance, safety, and durability. the cable is dried, and the top layer of the jacket is heated slightly so that printer markings can be imprinted on it. this research paper aims to explore the different types of cables, their applications, and technical and physical data. the manufacture of electrical cables, wire and wire products is a highly specialized process that requires the use of. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual.

From www.researchgate.net

Flow chart for evaluation of the minimum cost of the cablestayed Cable Process Flow Chart in this post, we’re going to talk about the common and crucial steps of cable manufacturing. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. First of all, let’s clarify two. this process is crucial in ensuring that cables meet the required standards for. Cable Process Flow Chart.

From powerquality.blog

Cable Links Designing in HVAC and HVDC Submarine Power Grids Selected Cable Process Flow Chart this research paper aims to explore the different types of cables, their applications, and technical and physical data. this process is crucial in ensuring that cables meet the required standards for performance, safety, and durability. Figure 2 shows the production. the manufacture of electrical cables, wire and wire products is a highly specialized process that requires the. Cable Process Flow Chart.

From www.presentationeze.com

Process Flow Chart PresentationEZE Cable Process Flow Chart Figure 2 shows the production. the manufacture of electrical cables, wire and wire products is a highly specialized process that requires the use of. this research paper aims to explore the different types of cables, their applications, and technical and physical data. in this post, we’re going to talk about the common and crucial steps of cable. Cable Process Flow Chart.

From hitexcables.com

HITEXPLUS Wires & Cables. Manufacturing By Jay Cable Industries Cable Process Flow Chart Figure 2 shows the production. the cable is dried, and the top layer of the jacket is heated slightly so that printer markings can be imprinted on it. First of all, let’s clarify two. in this post, we’re going to talk about the common and crucial steps of cable manufacturing. the manufacture of electrical cables, wire and. Cable Process Flow Chart.

From mavink.com

Flowchart Connectors Cable Process Flow Chart the manufacture of electrical cables, wire and wire products is a highly specialized process that requires the use of. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. Figure 2 shows the production. this process is crucial in ensuring that cables meet the required. Cable Process Flow Chart.

From www.nimcokolkata.com

Extra High Voltage Cable manufacturers in Kolkata , Extra High Voltage Cable Process Flow Chart the cable is dried, and the top layer of the jacket is heated slightly so that printer markings can be imprinted on it. this process is crucial in ensuring that cables meet the required standards for performance, safety, and durability. First of all, let’s clarify two. the manufacture of electrical cables, wire and wire products is a. Cable Process Flow Chart.

From precmfgco.com

Cable Assemblies Guide PMCI Cable Process Flow Chart First of all, let’s clarify two. this research paper aims to explore the different types of cables, their applications, and technical and physical data. Figure 2 shows the production. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. in this post, we’re going to. Cable Process Flow Chart.

From www.smartsheet.com

How to Write Standard Operating Procedures Smartsheet Cable Process Flow Chart this process is crucial in ensuring that cables meet the required standards for performance, safety, and durability. Figure 2 shows the production. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. this research paper aims to explore the different types of cables, their applications,. Cable Process Flow Chart.

From www.researchgate.net

Welding processes flow chart at PWI. Download Scientific Diagram Cable Process Flow Chart this process is crucial in ensuring that cables meet the required standards for performance, safety, and durability. this research paper aims to explore the different types of cables, their applications, and technical and physical data. in this post, we’re going to talk about the common and crucial steps of cable manufacturing. the manufacture of electrical cables,. Cable Process Flow Chart.

From www.researchgate.net

The manufacturing process flowcharts for examples of electrical wires Cable Process Flow Chart the manufacture of electrical cables, wire and wire products is a highly specialized process that requires the use of. this process is crucial in ensuring that cables meet the required standards for performance, safety, and durability. First of all, let’s clarify two. in this post, we’re going to talk about the common and crucial steps of cable. Cable Process Flow Chart.

From polariscables.com

Submersible Pump Cables, Flexible Cables Supplier. Cable Process Flow Chart this process is crucial in ensuring that cables meet the required standards for performance, safety, and durability. First of all, let’s clarify two. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. the cable is dried, and the top layer of the jacket is. Cable Process Flow Chart.

From mavink.com

Cable Manufacturing Process Flow Chart Cable Process Flow Chart design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. in this post, we’re going to talk about the common and crucial steps of cable manufacturing. this research paper aims to explore the different types of cables, their applications, and technical and physical data. . Cable Process Flow Chart.

From www.pinterest.com

Punctilious Cable Manufacturing Process Flow Chart 2019 Process chart Cable Process Flow Chart this research paper aims to explore the different types of cables, their applications, and technical and physical data. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. First of all, let’s clarify two. the manufacture of electrical cables, wire and wire products is a. Cable Process Flow Chart.

From bceweb.org

Cable Manufacturing Process Flow Chart A Visual Reference of Charts Cable Process Flow Chart Figure 2 shows the production. the manufacture of electrical cables, wire and wire products is a highly specialized process that requires the use of. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. this research paper aims to explore the different types of cables,. Cable Process Flow Chart.

From www.slideserve.com

PPT Fiber Optic Cable Pulling PowerPoint Presentation, free download Cable Process Flow Chart in this post, we’re going to talk about the common and crucial steps of cable manufacturing. this research paper aims to explore the different types of cables, their applications, and technical and physical data. Figure 2 shows the production. design and assembly from the drawing board to finished wire harness requires step by step planning and a. Cable Process Flow Chart.

From www.researchgate.net

Flow chart showing the major stages of the system engineering process Cable Process Flow Chart the cable is dried, and the top layer of the jacket is heated slightly so that printer markings can be imprinted on it. First of all, let’s clarify two. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. in this post, we’re going to. Cable Process Flow Chart.

From templates.rjuuc.edu.np

Manufacturing Process Flow Chart Template Cable Process Flow Chart the cable is dried, and the top layer of the jacket is heated slightly so that printer markings can be imprinted on it. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. Figure 2 shows the production. the manufacture of electrical cables, wire and. Cable Process Flow Chart.

From br.pinterest.com

Process Flow Chart Template, Process Flow Diagram, Process Map Cable Process Flow Chart Figure 2 shows the production. design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual. this research paper aims to explore the different types of cables, their applications, and technical and physical data. in this post, we’re going to talk about the common and crucial. Cable Process Flow Chart.